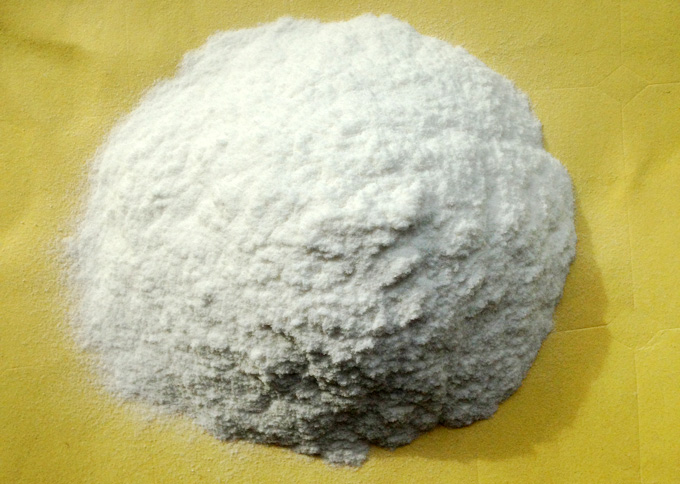

hpmc hydroxypropyl methyl cellulose

Hydroxypropyl Methyl Cellulose (HPMC) is non-ionic cellulose ether made from natural high polymer cellulose by series of chemical processing. It is odorless, tasteless and non-toxic white powder, which could be dissolved in cold water to form transparent and thick solution. It possess thickening, binding, dispersing, emulsifing, film forming, suspending, absorbing, gelling, surface activity, water maintaining and protective colloid properties.

Hydroxypropyl Methyl Cellulose has a wide usage. The products from our company are mainly used in building material, coating industry, ceramics, agriculture, daily chemical and other industries.

Application Performance

(1) Water Solubility Soluble water in any proportion,the highest density depends on viscosity,and solution does not be effected by PH value.

(2) Solubility in Organic solvent HPMC can dissolve in some organic solvents or organic aqueous solutions such as ethylidene chloride,alcohol ones.

(3) Heat Gelling When their aqueous solutions are heated to a certain temperature, reversible reaction may occur,but its fast gelling can be controlled.

(4) Non-ion Electric Charge HPMC is non-ion cellulose ether,does not complex with metal ions or result in insoluble precipitations.

(5) Thickening Its water solution provides thickening effect whoich has to do with viscosity,density and system.

(6) Water-holding HPMC or its solution can absorb and hold moisture.

(7) Film-forming HPMC can be made into smooth,tough and elastic film which offers excellent oil resistance and antioxidancy.

(8) Anti-enzyme HPMC and its solution have good resistance to enzyme,and offer good viscosity stability.

(9) PH Stability HPMC is stable in acid and alkali,no effect within PH3-11.

(10) Surface Tension HPMC in solution provides surface activity,playing a role of emulsification and protection of gels.

(11) Inertness of Metabolism Used as additive of food and medicine,it is non-nutritious, heatless, does not change metabolism.

(12) Dispersiveness HPMC can reduce interface tension,making dispersive phases disperse to size-suitable granules.

(13) Coherence Can be used as pigment,adhesive agent for paper,also used in coating and cohesive auxiliary material.

(14) Lubricity Can be used for rubber,asbestos,cement and ceramics to reduce friction and improve the pumping-adaptability of cement slurrry.

(15) Suspension-Assistance Can prevent solid granules from setting down.

(16) Emulsification Owing to reducing surface tension,it can stabilize emulsion.

(17) Protection of Gels A protective layer forms on the surface of the dispersed drops. which prevents drops from agglomerating,thus stabilizing gels.

Application Guide

Tile Adhesive

(1) Using HPMC, tile adhesive will easy to mix with water without lump appeared and saving time. Due to the more rapid and efficient operation, we can improve the workability and reduce the cost.

(2) The water-retaining property of HPMC extend the drying time of mortar, so as to improve the efficient of fixing.

(3) HPMC provide good bonding effect with highly skid resistance.

Cement-based plastering Mortar

(1) HPMC can improve the uniformity of plastering mortar, making it easy to coating, at the same time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

(2) With high water retention, HPMC can prolong the working time of mortar, improve work efficiency, and help the mortar obtaining high mechanical strength in solidification period.

(3) HPMC can control air infiltration, to eliminate the tiny cracks of coating, to format the ideal smooth surface.

Masonry mortar

(1) HPMC can improve the adhesiveness between mortar and masonry. And the water-retaining property of HPMC is useful in raising the strength of mortar.

(2) HPMC improves the lubricity and plasticity of mortar, so as to make the construction easier, to save time, to reduce the cost.

(3) For superabsorbent masonry, it is more important to use HPMC in the mortar.

Crack filler

(1) Excellent water retention of HPMC can prolong drying time of crack filler, it is helpful to improve work efficiency.Also, the high lubricity makes construction easier and more smooth.

(2) HPMC can improve the shrinkage resistance and crack resistance of crack filler, to perfect the surface quality.

(3) HPMC makes the construction surface fine and smooth. Meanwhile, the adhesiveness get improved.

Gypsum-based plastering and gypsum products

(1) HPMC can improve the uniformity of plastering mortar, making it easy to coating, at the same time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

(2) With high water retention, HPMC can prolong the working time of mortar, improve work efficiency, and help the mortar in obtaining high mechanical strength in solidification period.

(3) HPMC can keep the consistency unified, forming a good surface.

Self-leveling floor materials

(1) The viscosity of HPMC has the effect of anti precipitation.

(2) HPMC can enhance the product liquidity and pumpability, so as to improve the efficiency of the flooring.

(3) The water-retaining property of HPMC can avoid excess air infiltration. Therefore, crack and contraction are greatly reduced.

Water-based paint and paint remover

(1) The suspension property of HPMC can prolong expiration date by prevent solid precipitation. Meanwhile, it has good compatibility with other ingredients and biological stability.

(2) HPMC helps the product dissolving rapidly without lump.

(3) HPMC makes coating has good flow property and low splash, resulting a fine and smooth surface.

(4) HPM can increase the viscosity of the paint remover, make it not out of work scope.

Method of use

1. Fast Dissolving:

When being stirred,HPMC can dissolve in water and some organic solvents,if fast dissolving in needed,the following method is porposed:

(1) Heat the required water to over 85째C,gradually put in while stirring,cellulose dispersing in water,swelling into slurry.Stir and cool it down until it takes on transpar-ency which indicates full being dissolved.

(2) Heat half the water to over 85째C,put it in while stirring until it becomes slurry, then put in the residual cool water and stir it until transparency.

2. Prepare Gruel-like Mother Liquor for Use:

First prepare HPMC into high thick gruel-like mother liquor(the same method as above), when used,supplement adequate cool water and continuously stir until transparence.

3. Dry-Blending:

HPMC owns excellent compatibility,so it can be easily mixed dry with cement, plaster powder, pigment etc.a good effect can be obtained.